The treatments provided are particularly appreciated in the finishing of utensil surfaces and mechanical parts of various kinds, as well as in the finishing of moulds for industrial production. In this second case the mechanical polishing of the metal, thanks to the various stages of the process, reduces noticeably the roughness of the surface, diminishing the friction of the mould and prolonging its use and efficiency thanks to an esthetical and functional superiority of the product.

The polishing methods adopted by Essedue are suitable for cold working (cutting) as well as for hot working, such as die-casting, due to the reduction of the friction coefficient which favours the sliding of the aluminium and/or zama therefore delaying the deterioration of the runners.

Such production processes give excellent results even for those AUSTENIC stainless steels type “AISI 304” and “AISI 316”, with a high performance from the aesthetic point of view, and in the MARTENSITIC steels type “AISI 420” and “AISI 440” where, besides the aesthetic result, there is also an appreciable increase in the stainlessness, a characteristic particularly appreciated in the production of mechanical parts for the food industry and for the realization of surgical instruments.

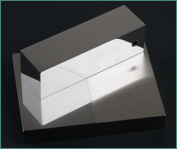

Essedue has chosen mechanical polishing because this presents various advantages respect to manual polishing, amongst which:

- the possibility of repeating the polishing cycle, which allows for a homogenous quality of the entire production,

- the global reduction of surface roughness thanks to which it is possible to obtain maximum planarity,

- the possibility of polishing areas which are manually inaccessible,

- the optimal surface finishing which permits an adequate support for various coverings and/or treatments (PDV, PLASMA, NITRIDIZATION),

- a minor cost which means saving.